Processing technologies for solid and flexible packaging materials from macroalgae

Summary

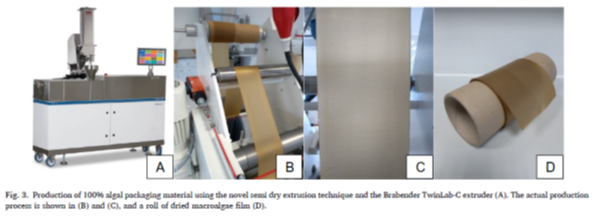

The non-degradability of most plastic packaging materials and the deficiency in recycling infrastructure on aglobal scale causes huge environmental problems. Production of packaging materials from natural macroalgae polymers is a very promising alternative to address the problems. The cultivation potential for macroalgae is huge and they are not in competition to food crops. Although the basic idea of using macroalgae polymers for thin film production was already described in 1934, the innovation has not progressed. The primary reasons include lack of social and political interests, and insufficient technical solutions for industrial production. An overview on the changing attitudes of the populace towards the indiscriminate use of non-biodegradable packaging materials and the state-of-the-art processes for solid and flexible packaging production from natural macroalgae polymer was presented. The highlights include a novel and promising approach to produce a 100% algae-based packaging material. The semi-dry extrusion of minimally processed algal biomass into different packaging products presents several benefits in terms of production cost, efficient use of water and energy resources, increased variety of products and reduced negative environmental impacts.

Significance

The paper highlights a novel and promising approach to produce a 100% algae-based packaging material. The semi-dry extrusion of minimally processed algal biomass into different packaging products presents several benefits in terms of production cost, efficient use of water and energy resources, increased variety of products and reduced negative environmental impacts.

Photos

Authors:

Ludwig Schmidtchen (Technische Universität Dresden, Institute of Natural Materials Technology)

Michael Y. Roleda (Division of Biotechnology and Plant Health, Norwegian Institute of Bioeconomy Research; Division of Food Production and Society, Norwegian Institute of Bioeconomy Research; Marine Science Institute, University of the Philippines)

Jens-Peter Majschak (Technische Universität Dresden, Institute of Natural Materials Technology)

Matthias Mayser (Brabender GmbH & Co.KG)

Read the full article: https://doi.org/10.1016/j.algal.2021.102300